Ensuring personnel safety without excessive cost at photovoltaic (PV) solar sites requires thorough engineering analysis to mitigate risks effectively. This involves processing extensive data and assumptions to determine the best risk reduction strategies. Here, we outline key factors and practices that influence successful grounding analysis outcomes.

Challenging Assumptions to Improve Outcomes

NEI understands that some projects may face significant increased grounding installation costs compared to initial engineering, procurement, and construction (EPC) proposals. However, sometimes we need to further examine assumptions to ensure accuracy and mitigate risks effectively. For example, an independent engineering firm once noted that NEI’s recommended mitigations appeared conservative. But upon review, it was evident that these differences were due to changes in underlying assumptions, rather than inaccuracies in our approach.

Simulation and Cost Reduction Opportunities

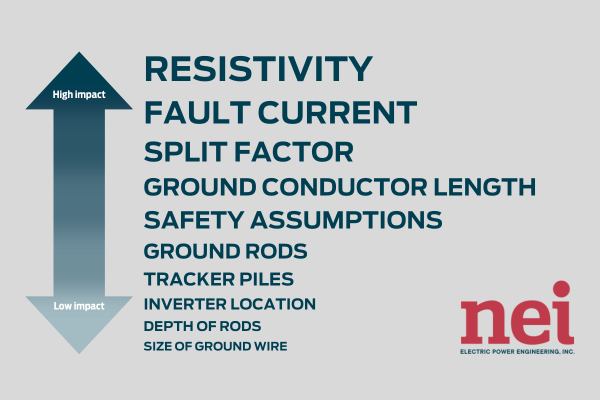

In recent projects, NEI simulated various mitigation methodologies to quantify the impact of assumptions. Generally, the inputs and assumptions are ranked as follows:

More specifically, we identified the following opportunities to reduce the cost of grounding:

Fault Level Assumptions

The short circuit data used to determine fault levels is typically the future grid magnitude, generally assumed as +20%, if not provided. The split factor calculation also adds an additional margin to account for uncertainties or variations in the actual fault levels, ensuring the system remains safe and reliable, even if the fault levels are higher than initially estimated.

The implications: These assumptions increase the fault current impact and grounding costs, which may be unnecessary given the decreasing likelihood of future fault increases due to the shift to inverter-based resources. The split factor calculation is also an estimate without an industry standard, so client risk tolerance is the primary consideration.

Soil Data Quality

The time lag between field soil electrical resistivity test (ERT) measurements and grounding studies often prevents retesting questionable soil data. To address this, we use ERT data to create lower, average, and upper models, determining worst-case potentials.

The implications: Utilizing an average soil model mitigates outliers and inconsistencies, providing a reasonable soil representation for the site.

Incorporating PPE

Personal protective equipment (PPE) is a standard requirement at PV solar facilities and can be integrated into the design process. Sites commonly require gloves and boots. In addition, IEEE 2778 recommends considering the electrical resistance of personnels’ boots, which can significantly influence grounding studies.

The implications: Designing with PPE in mind can lead to significant cost savings. However, it must match the site safety requirements and consider site specific risks.

Continuous Improvement & Future Recommendations

At NEI, we’re continually working to improve project outcomes. Here are a few ways we’ve adjusted our approach based on this recent review and analysis:

Early ERT Data Review

Reviewing ERT data early in the project provides a preliminary indication of its impact on grounding results.

Prioritizing Grounding Analysis Reports

We communicate key study findings early and more frequently to project stakeholders.

Owner Input

We gather early input from owners on preferred mitigation methods to ensure design approach consensus. For example, we may use bonding piles versus adding copper wire or other site-specific solutions to balance simplicity and cost. Regardless, owner preferences are paramount in finalizing the analysis.

Summary and What’s Next

This post highlights critical factors driving process improvements at NEI. Ensuring personnel safety without excessive cost at photovoltaic (PV) solar sites is key. In future blogs, we’ll explore soil model investigation, accurately depicting future grid conditions and leveraging advanced software features to enhance safety, mitigate risks, and reduce costs.