Overview

NEI excels beyond high-voltage engineering design; our expertise extends to understanding maintenance of low-voltage equipment—an often overlooked but crucial aspect in the world of power engineering design. Despite their lower voltage, the sheer quantity of these components can significantly impact and even multiply cost considerations.

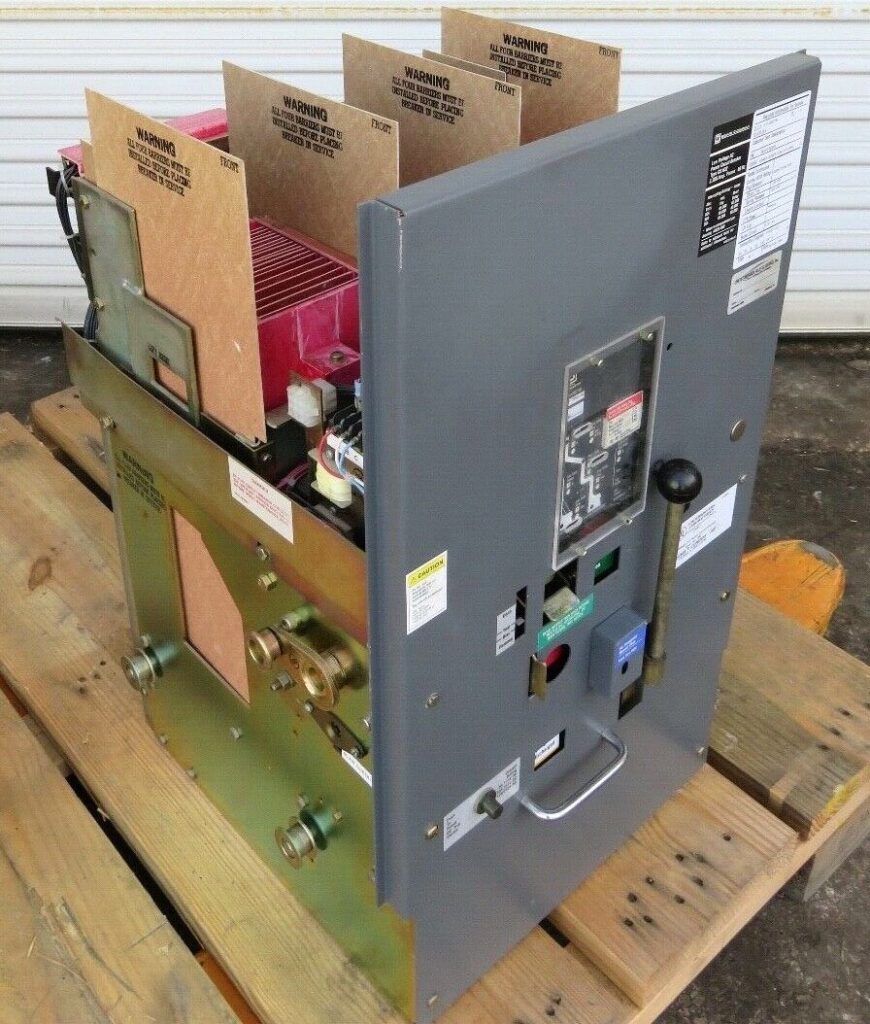

When developing a maintenance plan for low voltage circuit breakers, there is some nuance in deciding which type of testing is best for each application. Below is a brief discussion on circuit breaker primary and secondary injection testing.

Understanding Primary and Secondary Injection Testing

Primary injection testing involves using an external current source to create an overcurrent condition through the circuit breaker’s primary contacts to functionally verify breaker trip unit and tripping mechanism operation within acceptable time tolerances.

Secondary injection involves the use of test sets produced by the circuit breaker manufacturer which connect to an electronic trip unit.

Secondary injection can be used to verify trip unit health and functionality, as well as tripping mechanism functionality. This test method can only be used on insulated case, air, and power circuit breakers with electronic trip units. Thermal magnetic molded case circuit breakers cannot be tested via secondary injection. Availability and range of test set functionality varies widely between breaker/trip unit models.

Benefits of Primary Injection

Primary injection testing is generally viewed as the industry standard for circuit breaker testing, with every breaker capable of being tested this way. It is listed in the NETA Acceptance and Maintenance testing standards (ATS and MTS) as a requirement. All components of the circuit breaker – the current sensors, trip unit, trip plug, trip coil, and tripping mechanism – are verified as operational. Primary injection testing involves the breaker breaking current and extinguishing an arc, allowing for a significant level of confidence in breaker operability.

Challenges Presented by Primary Injection

- One must take several logistical challenges into consideration when determining if primary injection is the best option for their facility.

- An outage must be taken. As connection to the primary current path is necessary, the breaker must be removed, or both line and load sides of the breaker must be de-energized.

- Test power must be provided for the primary injection test set. For larger current test sets, this is typically either 240VAC or 3-phase 277/480VAC. This can come from facility gear that is not included in the outage, or can come from a temporary generator, but must be near the test set (typically within a few hundred feet).

- The test sets used for primary injection can be large and heavy, presenting challenges to transporting them close to the gear. Any equipment elevated above or located below ground level will require elevators or lifts to move the test set. A 50kA test set (commonly used to test a large 4000A main breaker) can consist of 2-units, one weighing ~300lbs, and one weighing ~500lbs. Despite having wheels, these test sets cannot be easily moved in dirt, rock, or other uneven surfaces.

- Due to these logistical considerations, and time required to perform the testing, primary injection can be relatively expensive.

Benefits of Secondary Injection

Since the ability to secondary inject is fully dependent on the type of trip unit and circuit breaker installed, below contains highly generalized aspects of secondary injection.

- Secondary injection test sets are typically small, highly portable test sets powered by 120V or do not require external power, and interface by plugging into the front of the trip unit.

- For some breaker models, non-tripping tests can be performed, allowing for trip unit health check without taking equipment out of service.

- Common circuit breaker failure mode is a faulty trip unit or trip plug, which can be identified via secondary injection.

- Significantly less time intensive than primary injection and cheaper relative to primary injection.

Conclusion

Developing a maintenance plan that involves proper cleaning and lubrication as well as testing is important to ensure the equipment’s long lifespan and functionality. NEI has the expertise to assist with determining which testing would be best suited for your equipment and facility.

Connect with an Expert

For guidance on engineering solutions that improve infrastructure, NEI provides expertise. Contact us for innovative approaches to your energy projects.